How an MES solution saves thousands of plant floor hours & millions of dollars

What If There Was a Way for You to Identify Potential Plant-Floor Failure Points Before They Happened?

An MES System provides factory insights so you know how, where, and why a product’s quality, a production process, or a machine is about to fail.

Did you know that a Manufacturing Execution System (MES) can deliver the insights you need to know how, where, and why a product’s quality, a production process, or a machine is about to fail? As well as what to do about it? It’s true! This can save you thousands of hours, millions of dollars, and most importantly customers’ trust. While there are many issues MES software can address, the most urgent and quickly resolved are related to visibility and control across the shop floor and plant, including:

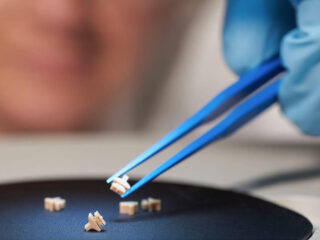

>> Troubleshooting product quality problems

>> Eliminating time wasted tracking the status of jobs in production

>> Removing the road blocks that create longer cycle times and lead times

>> Avoiding unnecessary shutdowns of production lines

>> Solving supplier quality and compliance problems

> DOWNLOAD THE WHITEPAPER to learn how an MES solution can provide you a 360-degree view of your manufacturing operation. Discover how you can eliminate the top five manufacturing challenges that could impact quality, production, inventory, customer satisfaction, or profits.